For volumetric building, it’s farther than you think

By Bob Schieler

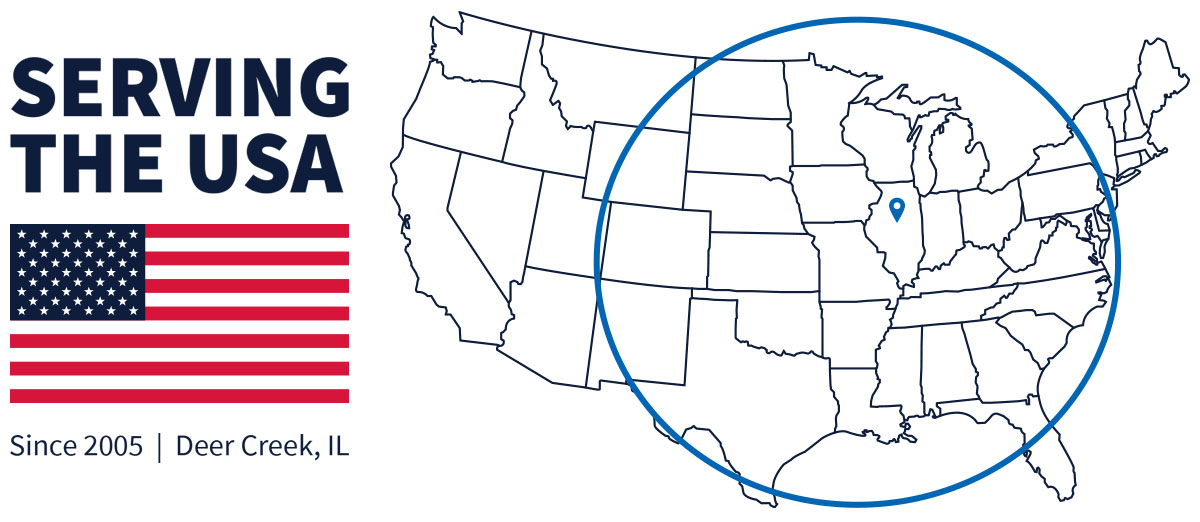

When considering whether to build volumetrically, traditional thinking says that a project needs to be within less than 500 miles away from the modular building facility to be economically feasible. While that’s true for most volumetric builders, that’s not the case for us. At Homeway, we have projects almost 1,000 miles away from our Deer Creek building facility in Illinois.

The reason modular projects are usually within 500 miles of the construction facility is quite simple: transportation costs. Typically, the further the project is away, the more cost prohibitive it is. But that’s not the case anymore.

So, how are we able to make it work? There are many reasons, but it comes down to more competitive transportation costs, experience, attention to detail, refined processes, and the ever-increasing costs of traditional building.

In the past, there were only a few options for transporting mods and the price per mod was very high. This created additional project costs and when compared to traditional building, might make it cost prohibitive.

But our approach to modular has become more streamlined not only in production (utilizing lean manufacturing practices, in particular), but also in transportation. Less than 10 years ago, we only had a limited number of options for transportation. But now, there are more transportation firms with experience in transporting mods longer distance, which creates more competition – which results in more economically feasible bids.

Also, lack of experience by many GC’s who don’t have a lot of experience with modular building which leads to higher budgets because they pad their costs to cover transportation contingencies that they didn’t have the knowledge or expertise to plan for. However, that’s not the case with our approach to volumetric building.

We have been a leader in the volumetric building industry for 19 years. And during that time, we’ve not only refined the volumetric building process, but we’ve also refined the transportation process which allows mods to be transported efficiently and effectively up to 1,000 miles away – that includes going to states like Pennsylvania, North Carolina, Texas, and Colorado.

In addition, the time required for traditional building has increased, according to the 2022 Survey of Construction (SOC) from the Census Bureau. For multifamily building construction, the average length of time to complete a traditional construction project was 19.8 months in 2022, which was 2.3 months longer than in 2021. For modular, the average time of construction for multifamily buildings is about 30-50% shorter, according to the American Institute of Architects.

During that same time, the overall cost of traditional building has increased, while our modular building costs have remained steady. This has happened for a variety of reasons – a decrease in the availability of skilled labor, supply chain interruptions, higher on-site building costs, and projects that just take longer because of intangibles like fluctuating weather conditions. Just the opposite has occurred in modular building.

So, with the ever-expanding time frames for traditional building combined with increasing costs and a paucity of skilled labor, our approach to volumetric building – with its consistent costs and streamlined processes – is becoming a more competitive option for projects near and far – as far as 1,000 miles away.

More Industry News

Now Hiring

Now Hiring